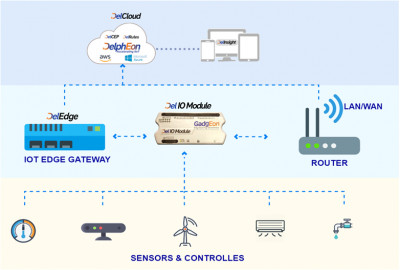

One of the main challenges in factory digitization is collecting different data types from existing, old and heterogeneous machines on the factory floor. Gadgeon’s flagship product provides a way out of this.

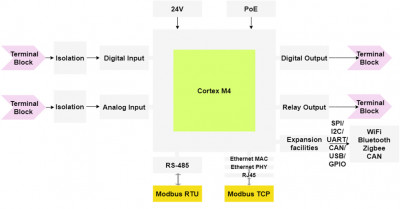

PoE,TCP/IP, Web Server, Modbus TCP server, Modbus RTU Serve

802.3af PoE, 10/100 Ethernet, RS-485, 1kV Isolated 8 Ch 24V Digital input, 4 Ch 24V Digital Output, 4 Ch 230V/2A Relay Output, 1kV Isolated 4 Ch 0-10V Analog Input.