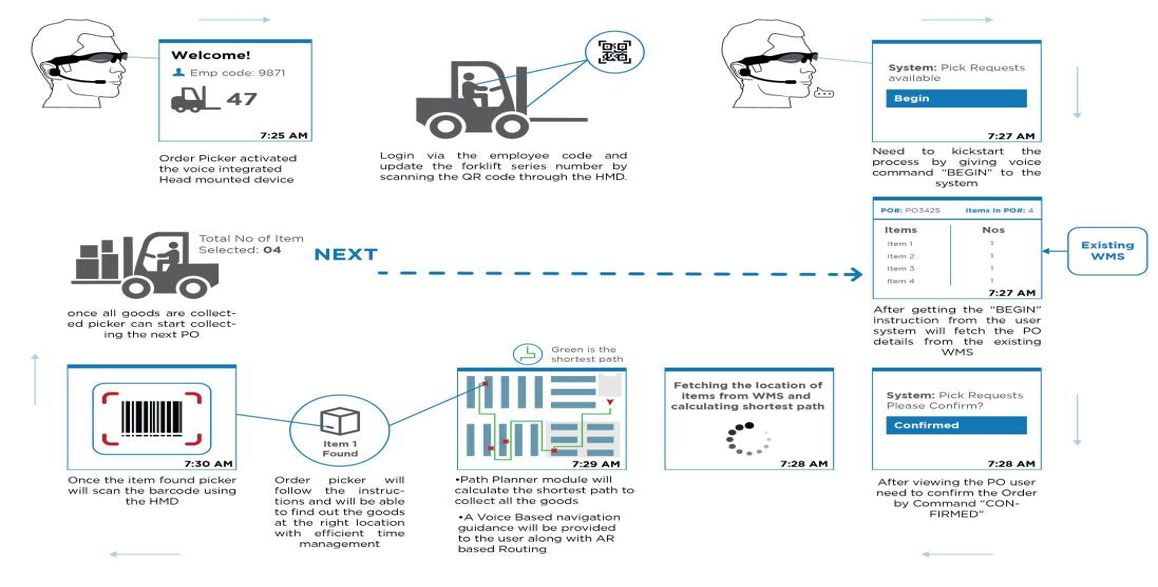

A Warehouse management system provider wanted to develop an efficient and accurate solution for their order picking challenges. The current manual order picking process has challenges like low productivity, expensive order picking errors were common due to wrong placement of inventory items, longer order picking cycles, increased cost so on.